Panacol’s Advanced Adhesives:

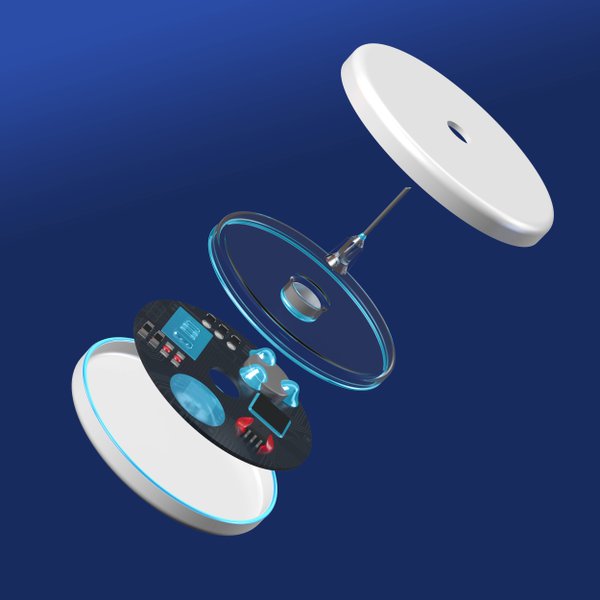

The proliferation of wearable patient monitoring devices has ushered in a new era of healthcare. These devices, such as diabetes sensors for tracking blood glucose levels (GCM) and wireless monitors transmitting vital patient data, demand precision, reliability, and safety for direct skin contact. Panacol, in partnership with Scheugenpflug and Dr. Hönle, has developed a comprehensive range of specialty adhesives tailored to the exacting standards of medical device manufacturers.

The Perfect Bond: Panacol’s Medical Device Adhesives

Panacol’s medical device adhesives boast outstanding adhesion properties to commonly used medical-grade substrates like polycarbonate, polyimides, polyamides, stainless steel, and ceramics. These adhesives undergo rigorous biocompatibility testing, aligning with ISO 10993-4/-5/-10/-23 and/or USP Class VI protocols.

Tip: Please fill out this form to determine whether or not you or a friend are eligible for a CGM and, Also learn about Sensor-based Glucose Monitoring

Within this adhesive family, LED-curable UV acrylates and UV epoxies stand out for their rapid curing cycles, ideal for high-volume production tasks such as needle/hub assembly, component attachment, and enclosure sealing. With a range of viscosities available, these adhesives offer versatility to match component configurations and assembly processes. Fluorescent variations enhance quality control through in-line vision systems. Need to Know Abbott FreeStyle Libre 14 Days

Also, the lineup includes electrically conductive adhesives and conventional thermosetting epoxies, addressing connectivity and attachment requirements for PCB and electrical component assembly. Some epoxy options prioritize high ionic purity, crucial for mitigating PCB corrosion risks. Panacol’s silver-filled electrically conductive adhesives can replace solder joints and adapt to bendable or flexible wearables.

Read Guide about Wegovy Dosage Guide: The Best Way For Weight Loss

Precision Matters: The DosPL DPL2001 Micro Dispensing Head

Accurate and consistent adhesive dispensing is paramount for medical device assembly. For precision in dispensing even the smallest volumes down to the µl range, the DosPL DPL2001 micro dispensing head from Scheugenpflug, an Atlas Copco Group member, is the top choice. It ensures reliable application, achieving glob tops as tiny as 0.003ml, dispensing accuracies of under 0.5%, and creating the thinnest lines on plastic housings with precise start and stop points.

The DosPL DPL2001 operates on volumetric dispensing principles, reliably detecting viscosity fluctuations to maintain consistently high precision in bonding contours.

Must Read about The Link Between Ultra-Processed Foods and Depression Risk

Swift Curing with Dr. Hönle’s LED Systems

Panacol’s UV acrylate and epoxy adhesives harden rapidly, thanks to their unique formulations. Dr. Hönle’s LED curing systems maximize this curing process’s efficiency, enabling the shortest cycle times and the highest throughput. The tested system combines Panacol’s adhesives with Hönle’s LED Spot 40 IC, operating at a 405nm wavelength. This compact LED head seamlessly integrates with Scheugenpflug’s DispensingCell DC803 multifunction robotic cell, minimizing parts handling and associated risks like component movement, contamination, and adhesive migration. This integrated system ensures the adhesive bonding process meets the highest quality standards with peak efficiency.

Whether it’s batch production or continuous flow, the integrated adhesive bonding systems offered by Panacol, Scheugenpflug, and Hönle are poised to meet the exacting production demands of medical wearables, ensuring the highest levels of quality and efficiency.